Linear Vibration Motor Introduction

Posted in 2018-06-02 11:10:56 in Tech Blog, 2 Comments

In recent years, with the increase of consumers’ requirements for tactile feedback, linear vibration motor have become more and more widely used in mobile phones. But what is linear motor? What is the difference between it and traditional motors? Then we’ll introduce the linear motors in detail.

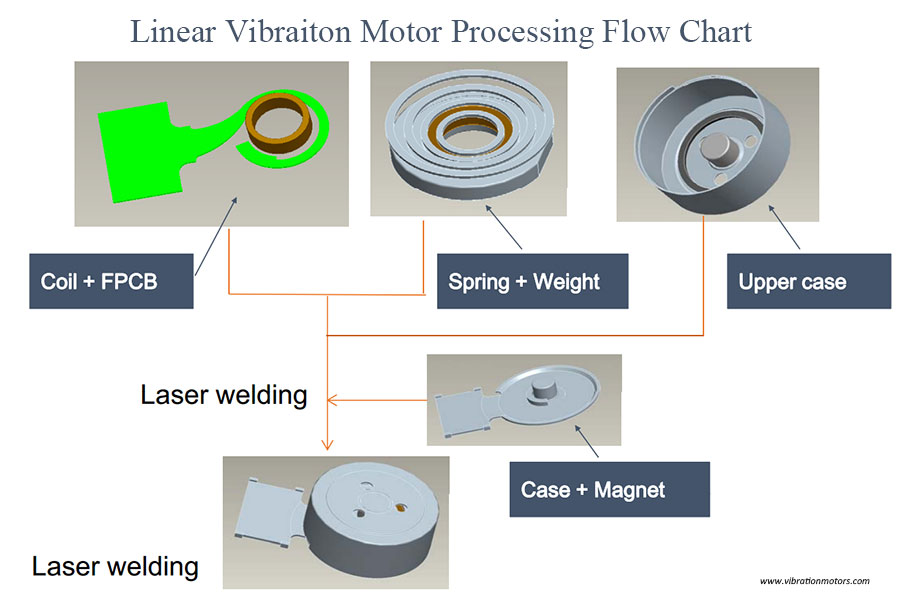

There are two basic types of vibration motor. An eccentric rotating mass vibration motor (ERM) uses a small unbalanced mass (we usually call it eccentric weight) on a DC motor, when it turns it creates a centrifugal force that translates to vibrations. A linear vibration motor contains a moving mass attached to a wave spring, which creates a force when driven.

We can clearly see the working status of the linear motor and ERM motor in the above picture. In order to let you understand the working principle of the linear motor, I specifically attach the picture as follows. You can clearly understand the principle of the linear motor from the figure.

Principle:1. The coil is powed by AC 2. Internal magnet has N/S polarit

Under the above conditions, the electrified coil generates magnetic field to move the magnet to attact the repel, so that spring can drive the mass block up and down to generage force.

Compared to the ERM vibration motor, the linear vibration motor has faster acceleration. It takes only 50ms from the standstill to the highest vibration level, while the ERM vibration motor needs 100ms~200ms. Higher accelerations result in better haptic feedback, so more and more mobile phone brands are starting to use linear motors instead of traditional motors.

Because of the mechanical structure, the ERM motor have brush abrasion during the working process. But, linear vibration motors are effectively brushless as they use a voice-coil to drive the mass. This means that the only moving parts that are prone to failure are the springs. These springs are modelled with FEA and are operated within their non-fatigue zone. So the lifetime of the linear motor is usually more than five times that of the traditional motor.

Considering Baolong Company?

Email us at:

sales@baolong.com

Or call us at:

+86 (0577) 62572888